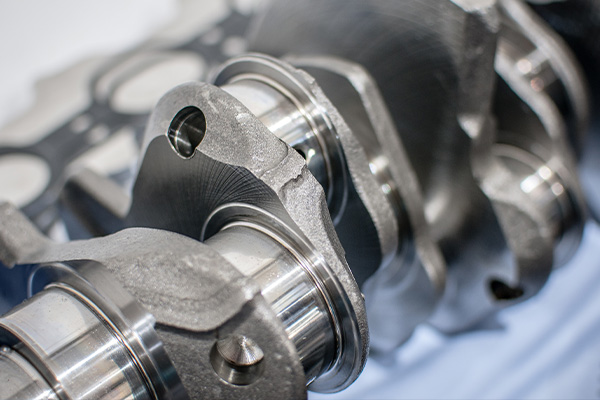

We use a Peterson-Berco Crank Grinder to adjust crankshaft rod and main journals. Over time, an engine’s crankshaft rod and journals (where the pistons connect to the crankshaft) can become worn. Sometimes we see damage caused by bearing decay and/or destruction. Smoother journals generally result in more efficient and longer lasting engines.

The crankshaft grinding process consists of removing a small amount of material from the rod and main journals to adjust the part to specific tolerances. Having a perfectly smooth journal is a critical factor in the efficient movement of the piston in the engine. Therefore, the crankshaft must be carefully prepared for each engine build.

Following crankshaft grinding we take precision measurements and adjust clearance by installing new bearings which are sized to compensate for the new clearance difference, providing proper oil flow at the diameter of the journal and killer performance.