Misaligned bores in machined parts can lead to vibration which, depending on the application, can result in catastrophic engine failure. (this would be bad…) In some cases, even a small amount of misalignment will result in an engine running poorly, or not even at all. This is what makes this type of repair so common.

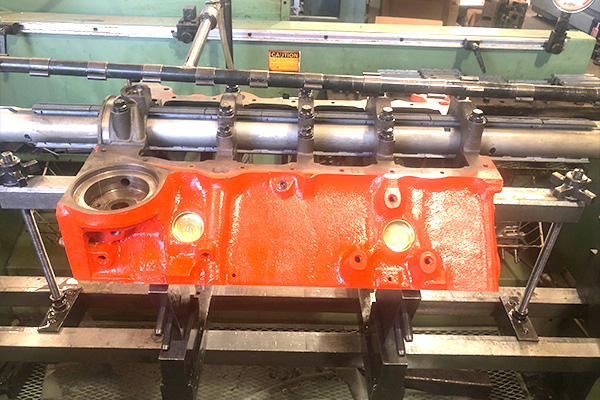

Line boring is when we enlarge a hole that has already been cast, thus making the center lines of two or more bores collinear. Such collinear bores are commonly found in engine blocks and gearboxes. Precision is paramount in these machines, especially for high performance, high horsepower, and high revving engines.

Line boring jobs often depend on the number of bores and how damaged or worn a bore may be.

Bring your job in and let our expert technicians evaluate your project. Estimates are free.